Tractor Scrape Blades

Scrape Blades are one of the most common tractor attachments you'll find. Chances are if you own a tractor you own a scrape blade or looking to get one which is why you've found this site. Scrape blades are designed to move dirt, snow, topsoil, gravel, and used as a leveling or smoothing off tool. A standard scrape blade is basically a concaved plate of metal that you pull behind a tractor, however now-a-days there's a lot more options and features when it comes to scrape blades.

I'm assuming you are on this page because you are in the market to buy a scrape blade and want to learn a bit more about them. It's a good thing because with a number of different styles and features you want to make the right selection for the job. Also keep in mind possible future uses so you can get the most for your money.

Different Uses for Scrape Blades

As I mentioned earlier scrape blades are used for to move dirt and other types of elements by scrapping the blade along the ground either with a straight blade or angled. If you live in the northern states where you get a lot of snow scrape blades are very common and are a perfect attachment to move snow around and clear off driveways and parking lots. Airports use them to clear off runways while construction crews use them to clean up construction sites.

Scrape blades also known as grader blades for those that use them to level or grade driveways and dirt roads. If you happen to live on a long dirt drive or dirt road often times you end up with deep holes where the rais has washed away parts of the drive. Using a grader blade or land leveler to level out the dirveway and fill in the ruts and puddle holes is much easier with the right equipment.

Features and Different Types of Scrape Blades

Standard Scrape Blade

The standard scrape blade is a basic blade that you pull behind a tractor however there are a number of different features that you can get such as a movable blade with forward and reverse angle positions. Some scrape blades offer offset and tilt positions. Another very important feature to look for when buying a scrape blade is a replaceable cutting or razor blade and how easy is it to chance.

Box Blades

A number of attachments have blades that can be used as scrape blades including Tractor Box Blades. Box blades are not only for scraping but can be used for pushing as well. You'll also find a lot of box blades come with ripper shanks that are built into the frame and used for digging and breaking up the ground or high spots. This helps displace the dirt and fill up the box blade to be moved. A few things to look for when looking to buy a box blade is that the shanks are actually built into the frame and solid pins to lock them in place.

Land Levelers

Land Levelers / land graders are a perfect tool for driveways and dirt roads. Designed similar to a box blade only with an open back and double angled blades. While it can be used to scrape other things it's main purpose was for leveling out driveways and such.

Dozers

Dozers are a type of scrape blades that do more pushing than pulling. You'll find a lot of dozers on trucks in the northern states to push the snow and clear the roads. The nicer dozers use a type of rubber blades to prevent from tearing up the roads. One of the features you can find on dozers is hydraulic angles which a lot nicer than the manual.

Check Out This Video of Scrape Blades in Action

|

|

|

Order A Scrape Blade Online Today

|

Tractor Scrape Blade Attachments

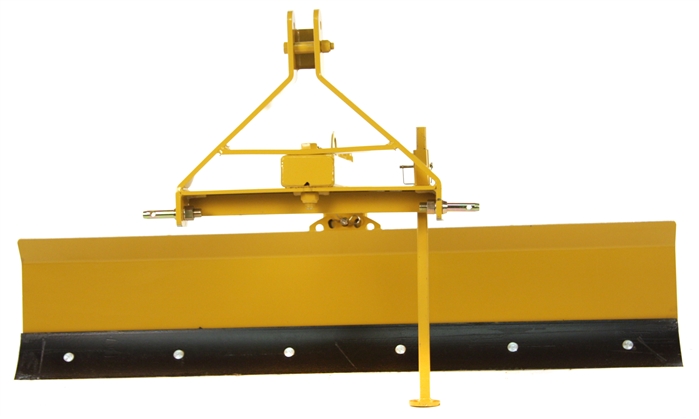

We have designed this scrape blade as the best value on the market, focusing on a strong blade that will last a lifetime, without adding unnecessary components. All the parts of this scrape blade are made in our factory except for the cutting edge which is made by Valk, an American company. With a solid c-channel brace on the back, and more adjustment options than the competition, you will easily see the value in this blade. This scrape blade is rated for 25-50 HP tractors without cabs, and up to 40HP tractors with cab enclosures due to extra weight.

|

|

Tractor Land Leveler Attachments

Fill in pot holes, washed out areas, and low spots, or a washboard area, and recover gravel with the Everything Attachments Land Leveler-Land Plane. The Everything Attachments Utility Grader, has two angled cutting edges on this leveling box, and is available in 60", 72", 84", and 96" widths. The easiest to use implement for smoothing gravel driveway or roads, hook up to your category 1 or 2, 3 point hitch, adjust your top link until flat and level, and immediately improve your driveway or roadbed as the material flows over the first edge and is leveled by the back edge. You can use your adjustable down link from your 3 point hitch to make a crown on your road, if desired. The Everything Attachments land leveler is built with 1/4" side plates, 3" square tubes, and 3/8" frame and hitch. The improved Clevis type hitch is for Category 1 & 2 hookup, where lift arms attach, measures 25 1/2" inside for 7/8" pin size, category 1 hitches, Category 1, Quick hitch compatible, and 31" inside for 1 1/8" pin size, category 2 hitches. Attachment pins are included for the lift arms.

|

|

Compact Tractor Front Scrape Blade

The Construction Attachments Front Scrape Blade is designed for compact tractor loaders up to 50 horsepower. Featuring a 4-Way blade with up to 30 degree angles either left or right is what makes this scrape blade perfect for scraping snow and debris. Manual or Hydraulic angle operation allows you to choose whats best for your application and having the ability to convert from manual to hydraulic is perfect for upgrading in the future. 22.5" Spring-trip moldboard with a 75 degree angle available in 60", 72", and 82" wide models.

|

Hi, I'm Ted from Everything Attachments. We're here today with a new scrape blade that we have. We try to build the best of everything, but there's also a big need for customers that simply are not going to use their attachments constantly in a commercial business. We looked at doing a lot of different things with this blade. What we're going to end up doing is we're going to have a bunch of different styles of blades so you get what you want.

This is not a quick attach blade. To be a quick attach blade, we have to remove this plate. It just keeps adding up to more and more money to what it takes to do that. Ninety percent of the people or more are not using a quick attach. To make it a quick attach blade, we have to add a kickstand and just more and more parts.

What we're trying to do is we're real close to a blade that we were selling that was red, but what we've done for you we're making this on much more precision machinery. Our press break and everything is brand new. It's perfect. It leaves good nice pins with the exact degrees. When you put your top link pin in, these are perfectly level. We're using a pickled and all steel which doesn't have scale and stuff on it because we're cutting this with a laser. We're using an automotive quality finish also. Instead of buying $18 a gallon paint, we're buying $45 a gallon paint. It's going to last longer for you.

We're also using American made cutting edges from Vault. We've added some extra adjusting holes in the offset. We've added some extra holes in the angle back here and in the tilt. We'll just go through what we've done. We're going to sell it at the exact same price as we were the TRI blade and the medium duty. But you're just going to get a lot tighter fit and clearances, you're going to get a better paint job, and you're just going to get an overall better fit and finish. We'll go through that as we go.

These here have been rounded. That's going to keep you from tearing your blue jeans and stuff. I've torn a hundred pairs of them. Same way down here. This is rounded. You're not going to tear something there. This is a 3/16 capped tube that is a 3 by 5 tube. We're using a Grade 5 bolt here that is an inch and a quarter. We've got seven different offset locations. The other blade, I believe, only had five. We've put them in locations that match.

The new we've gone from five, which would be 10. We've gone from 10 adjusting holes in the back to 14. That's going to give you a lot more combinations to offset your blade and still keep your blade going the angle that you want to. We've added a hook. We can pick it up without having to wrap a chain or something around it to get it on the palate, to try to scratch it up as least as possible so we can band this down for shipping. You can get it off the truck. You can move it around without having to do it. We can't really control what the shippers do with it, but we leave it in a new condition when it leaves us. We rounded the top of the edge here just a little bit, just one more thing to keep you from tearing your blue jeans.

When we talk about fit and finished, it's things like – this is a half-inch thick plate, and when you weld this to it, on this particular blade, this piece right here is 3/8 of an inch thick. On the other blade, it was 3/16 of an inch thick. It’s twice the thickness. When you weld this to this, on the other blade, what it tries to do is it tries to draw that piece of metal. It tries to bow it from the heat. There was over a half an inch of bow in this plate. A little bit doesn't hurt because it actually makes it easier for you to spin and get up under the tube. This has 1/16 of an inch of bow in it, and we set that in a jig instead of just cold welding it on the table, because that's going to create a half an inch of bow in it.

This is a 3/8 true tube instead of being 3/16. This is also an inch and a quarter bolt on the back. Now we've added some more angle positions in the back here. Instead of just one angle each way on 30 degrees, we've put a 15 and a 30. Thirty degrees is awfully aggressive for the small mid-sized tractors that are going to be using this from, say, 25 to 50 horsepower.

We also discovered that on the other blade, this seat channel here, which is a three-inch seat channel, was two separate pieces. What we did was we extended this out just enough to get this through. Turn me back to the side. Just a little bit here. Right there. We extended this plate out here where we still had room for the head of the nut to weld in there, and then this seat channel goes all the way from one side to the other. By making it the other way where you stop at each side and put two short pieces, you definitely have a weak spot right here when you take a hard hit on the end. Then we’ve rounded these end caps and everything just to make it nice, neat, and keep you from getting torn up.

We think we’ve come up with a blade that has a really good finish. It's really a tight fit on everything. With a laser, we can get down to just a few thousandths of an inch on all the holes and where the pins go through. It's going to be what we call our value blade. That doesn't mean it's cheap in any way. It's just a good value for you. If you're not going to use it a lot, it's the least expensive six-way angle-tilt blade of a good quality that I know of. We're going to sell it for the exact same price as we were the Tennessee River Blades.

I think for you in the end, when you get it delivered and the quality for what you're getting, simply you're getting a better value. That's why we call it our value blade. We will be coming out with many more blades over the next couple of weeks. We're working hard at our new factory. If you've got any questions or emails, give us a call or email. We'll help you size the blade for your tractor. This model will come in a five-, six- and seven-foot blade. Just give us a call or an email. We'll be happy to help you at Everything Attachments.

This is on a Bobcat 450. It's a 45-horsepower tractor. Something 45 to 50 horsepower is about the size that this is designed for on the larger side. We do make it in a five-foot so it will be okay with a 25-horsepower B-Series Kubota or something. It's one of the lighter, stronger blades. We try to make it strong. We try to make it light for the smaller tractors to still be able to put all the functions in it, which is offset, tilt and angle.

Almost all blades will angle. Some will tilt in some ways, some better than others, and very few offset in the smaller blades. But this blade does have all the functions. This is the prototype blade. We have made a few changes on it. I'll tell you what those are. One of them is this last hole, which is in a blade that we looked at, is just too far over, so we chose not to put it in there. It goes all the way over to there, and that's just too much angle, so we came back a hole which is right there. The paint was still stuck on it from when we left this from over the weekend. That's how fresh this was from when we did it.

That's going to be the last hole. It's going to have seven holes in it, which we added from five to seven, just leaving out the last two and then putting more in between. You've got even more adjustment there. On the angle of the blade, we also added some different… Now this one does not have it added, but we did go from the amount of holes in it now, which is five, to seven on each end. It increased the width of this plate about two inches.

It will turn all the way around. On the angle of it – let's go back to this side – right now, the furthest you can angle it is right there. That's plenty of angle, except when you go to offset it. When you go to offset it about right there, the blade starts becoming straight again. For some things, you would use it in the straight position, but for a lot of things, you won’t. If you're doing snow, you're trying to get your tractor on to where you've already scraped for the maximum traction. You want to get over as far as you can and you want to keep redirecting the snow to the left side.

We've added another hole here which is going to put you about right there. Then when you go to your furthest hole, you still have some angle to keep it going in that direction. This is just the prototype. The other ones are already being built, but it's the one we have to work with. It has been painted. It's the first one.

We do usually end up making at least two tries to get our prototype right when we're changing up different things and trying to make them better. Once you get it back to the center position, now we're going to do the tilt. The other blade that we looked, it only had one hole in each direction. It was a full 30 degrees. Thirty degrees is really aggressive. In fact, I need to raise it up a little bit. It lacks just a little bit of getting a full 30 degrees. That will probably get it. In fact, ground it into the pavement or the gravel.

That's 30 degrees. That was the only setting on the other blade. For most smaller tractors, that's just too aggressive. We chose to put in a 15-degree also. That's probably going to be your most commonly used tilt angle for cutting a ditch and so forth. Now, if you've got it fully tilted and you fully angle it, it's going to hit this beam. It does on all blades like this. There's no good reason why you would be fully angled and fully tilted, because usually when you want to tilt, you want a good square edge here to be cutting a ditch or something. You may angle it a little bit, but it won't let you angle it fully and tilt it fully. You do have more adjustments to do more things. Just keep in mind that's one that can't be done.

At Everything Attachments, we've added a hook on it here. We've made more precision parts. We've added different angles that make it better. We learn more and more every time we try to reproduce a blade that has been made before, try to make it better for you, try to give you a better value on the end – users or customers since we have no dealers, no reps, no distributors. Just give us a call or an email and we'll make sure that you size the blade right for your tractor.

The one thing about a blade – I try to rate it 25 to 50 horsepower, so really it almost can't get torn up. The deal on a scrape blade is, when you're using it in snow, you don't know what's under the snow. This blade would probably be fine in a using way with a 60-horsepower tractor. But it's when you catch that curve or something in the snow and the weight of that heavy tractor is what bends a blade. Just keep that in mind. It's not really the size of the tractor. It's what you're doing with the tractor. We're going to rate this from a 25-horsepower to a 50-horsepower compact.

Thanks a lot, give us a call or an email if you need any help.